- Home

- Products

- Press Brakes

- WC67K Series Hydraulic CNC Press Brakes

- DA41 Servo Drive CNC Press Brake

DA41 Servo Drive CNC Press Brake

Application

The DA41 servo drive cnc press brake is primarily used for the bending and processing of stainless steel, iron, copper and aluminum, and features a high production efficiency and bending accuracy. The DA41 servo drive cnc press brake uses upper and lower molds in different shapes, so that metal can be bent into various shapes. Through the use of a single sliding stroke, the material is quickly bent into shape, sand the workpieces with complicated shapes can be made by multiple bending. The DA41 servo drive cnc press brake can be widely used in the aviation industry, light industry, metallurgical industry, chemical industry, architecture industry, shipbuilding industry, auto industry, power industry, electric appliance industry and decoration industry.

| Model | Bending Pressure (Kn) | Bending Length (mm) | Column Distance (mm) | Throat Depth (mm | Slider Stroke (mm) | Max. Opening Height (mm) | Yl,Y2-axis Down Speed (mm / sec) | Yl,Y2-axis Back Stroke Speed (mm / sec) | Y1,Y2- axis Precision (mm) | X-axis Max Distance (mm) | Workpiece Linear Degree (mm/m) | X&R Axes Accuracy (mm) | Sliding Front Supporting Stopper Arms (PCS) | Back Stopper (PCS) | Main Motor (Kw) | L*W*H(mm) | Weight (T) |

| 630 | 1300 | 950 | 350 | 100 | 340 | 150 | 150 | 0.01 | 500 | >0.3 | 0.05 | 2 | 2 | 5.5 | 3100*1450*2050 | 4 | |

| 630 | 2500 | 1900 | 350 | 170 | 380 | 150 | 150 | 0.01 | 500 | >0.3 | 0.05 | 2 | 2 | 5.5 | 3100*1450*2050 | 5.8 |

- DA41/TP10 CNC system

- Servo controls the X and Y axis

- X axis and Y axis driving the automatic control

- HIWIN ball screws & linear guide with 0.02mm accuracy.

- America SUNNY internal gear pump with high-performance and low noise

- Germany EMB tubing connector

- Germany Busak hamban sealing element

- France Schneider Electrics

- Germany Siemens main motor

- Estun servo motor

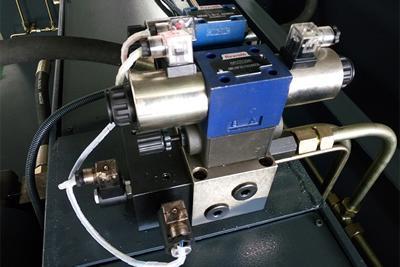

- Germany Bosch-Rexroth / America Forster hydraulic system

- Support arm for front supporter

- Hydraulic &electrical overload protection

- Equipping with 2+1 axises: Y-X-V

Features

1. The left vertical plate, right vertical plate, workbench and material pressing board are welded into an integrated structure, and use a tempering process to eliminate internal stress after welding. This results in the integrated structure having a high hardness and stability.

2. The frame and slider of the servo drive CNC bending press brake use a finite element analysis software in order to ensure machine reliability.

3. Hydraulic transmission: stable and reliable

4. Germany Rexroth or America First hydraulic system: high synchronization accuracy

5. The distance of the back gauge and slider stroke are controlled using the CNC system.

6. The cylinder is produced through casting, grinding and hard chrome plating processes, and is equipped with a sealing ring to eliminate oil leakages.

7. The hydraulic system uses an oil circuit integrated hydraulic system, and decreases the need for pipe installation.

8. The servo drive CNC bending press brake uses three-phase system power (380V) to supply the power, the control-circuit voltage (220V) is supported by a control transformer and the direct current power (+24V) is needed by an execution circuit electromagnetic valve, which is supported by the transformer and silicon rectifier.

The servo drive CNC bending press brake uses Netherlands DELEM-DA41S as its only CNC system. This system uses the latest electronic techniques, providing a set of unique solutions for the slider, back gauge, and import/export of the servo drive CNC bending press brake.

DA41CNC system

1. LCD display with high definition

2. Slider stop position control

3. Back gauge control

4. Angle program

5. Mold parameters setting

6. 100 procedures

7. Each procedure has 25 process

8. Panel type installation

9. Servo control; Frequency change control; Dual speed AC control

Germany Rexroth or America First hydraulic system that is easy to maintain and features a high performance.

By using the Siemens Motor, the service life of the press brake is increased, as well as decreases the noise levels of operation.

America SUNNY internal gear pump with compact structure and good oil absorption.

Germany EMB tubing connector is well sealed and high capacity.

Germany Busak Shamban sealing element; highly wear resistant, easy to install.

Servo motor with high performance

Heavy load linear guide rail guiding; Large lead ball screws transmission; High accuracy, fast speed and good stability

European style mold clamp connector

Having the fine-tune wedge block can adjust the effective use height of the clamp to ensure the flatness requirement among the clamps.

Mold

A set of standard molds makes it easy to change the molds

The integrated quenching technique; High hardness and grinding resistant

The mold can be designed according to client requirements

Optional CNC system

TP10 CNC system

1. 7.0 inch TFT screen with the 800*480 resolution or 10.4 inch TFT screen with the 800*600 resolution

2. The operating screen is not complicated and features a number of different functions

3. With the TP10 CNC system, the servo drive CNC bending press brake can interact with smartphones, service terminal devices and mobile PCs at long distances.

4. The Ethernet HMI provides different features for RS485 and Ethernet communication in real time and reliable, on the spot communication

5. With an automatic alarm, the machine is safer.

Jiashida is a sheet metal fabrication equipment manufacturer and supplier, offering all kinds of sheet metal metalwork machinery like hydraulic shear, press brake, punch press, plate roll bender and sheet metal shears, metal benders. We have well trained and experienced team and fully equipped machining equipment to guarantee that we offer good quality metalworking machines.

Index

sheet metal press brake, metal bending machine, metalworking machinery

Maanshan Jiashida Machine Tool Company

Add.: Bowang Industrial Park, Bowang District, Maanshan City, Anhui Province

Contact Person: Bert Chi

Fax: +86-555-6766722