- Home

- Products

- Shears

- QC12 Series Sheet Metal Hydraulic Swing Beam Shear

- QC12K Sheet Metal Hydraulic Swing Beam Shear with E200PS Controller

QC12K Sheet Metal Hydraulic Swing Beam Shear with E200PS Controller

Application of the QC12K sheet metal hydraulic swing beam shear with E200PS controller

The QC12K sheet metal hydraulic swing beam shear with E200PS controller is designed for the shearing process of metal fabrication used in a wide range of industrial operations such as aviation, metallurgy, chemical processing, architecture, shipbuilding, and automotive production. The machine is suitable for cutting steel, iron, copper, and aluminum workpieces. The shear uses an integrated steel plate welding structure, while the machine's rack features an integrated high temperature annealing to eliminate internal stress, providing good intensity and shock resistance. All of these factors contribute to a high quality shearing process with excellent precision.

| Type | Max Thickness (mm) | Cutting length(mm) |

Throat Depth(mm) |

Shearing Angle(°) |

Blade length (mm) |

Shearing speed (Cuts/min) |

Back Gauge Specification |

Front Holder Quantity |

Motor Power (kw) |

Oil Tank Capacity (L) |

Weight (kg) |

L*W*H (mm) |

|||

| <450N / mm2 | <700N / mm2 | Travel (mm) | Speed (mm/sec) |

Number (PCS) |

Length (mm) |

||||||||||

| 4 | 2.5 | 2500 | 100 | l°30' | 2600 | 10~12 | 600 | 180 | 3 | 800 | 5.5 | 220 | 3800 | 3040*1610*1620 | |

| 4 | 2.5 | 3200 | 100 | l°30' | 3300 | 10~12 | 600 | 180 | 3 | 800 | 5.5 | 290 | 5000 | 3840*1610*1620 | |

| 4 | 2.5 | 4000 | 100 | 1°30' | 4100 | 8~10 | 600 | 180 | 4 | 800 | 5.5 | 290 | 6500 | 4600*1700*1700 | |

| 4 | 2.5 | 6000 | 100 | l°30' | 6100 | 5~7 | 600 | 180 | 6 | 800 | 11 | 380 | 11000 | 6460*2100*3200 | |

- Estun E200PS CNC control System;

- Location control of the back gauge;

- Frequency converter controls the back gauge;

- Taiwan TBI ball screws & polished rod with 0,05mm accuracy.

- Germany Bosch-Rexroth hydraulic valve

- Germany EMB oil tubing connector

- Germany Siemens main motor

- France Schneider Electrics

- Hydraulic & electrical overload protection

- Light aligning

- 6CrW2Si is the special blade material to cut the stainless steel

Estun E200PS CNC system

The Estun E200PS CNC system adopts CAN bus technology, servos control the X axis and Y axis, and the control accuracy is high and the resolution can reach about 0.001.

The machine has the function of one key backup and recovery, the parameters can be recovered according to the requirement and decreases the maintenance cost.

The QC12K sheet metal hydraulic swing beam shear with E200PS controller has the function of self-diagnosis and real time alarm, thus making adjustment and maintenance easily.

Passing the CE identification.

1. With the sliding workbench and front material loading device of the QC12K sheet metal hydraulic swing beam shear with E200PS controller, feeding the material is convenient and ensures the workpiece will not be scratched while processing.

2. The material pressing device of the QC12K sheet metal hydraulic swing beam shear with E200PS controller adopts the parallel compaction cylinder and also features a rubber blanket. And when the sheet metal is not smooth, the material presseing device can stretch flexibly onto the sheet metal and do not scratch the surface of the sheet metal.

The sheet metal guillotine hydraulic shear is assembled with Schneider electric components for stable operation.

When the electric cabinet door is open, the machine automatically shuts off as a safety feature.

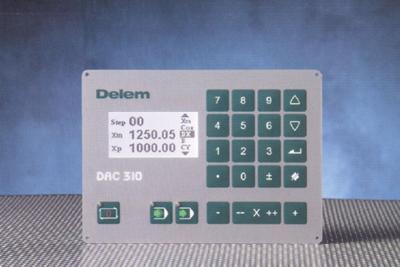

To the QC12K sheet metal hydraulic swing beam shear with E200PS controller, the DAC310 CNC control system can be added upon request.

* High definition LCD display 275*48 pixel

* The control of back gauge

* The control of the blade edge gap

* The control of shearing stroke

* The actual location of back gauge and program value display at the same time

* Shear count

* 100 procedures

* Panel type installation

* Servo control/ frequency changing adjustment control/two-speed alternating current motor control

Jiashida is a sheet metal fabrication equipment manufacturer and supplier, offering all kinds of sheet metal metalwork machinery like hydraulic shear, press brake, punch press, plate roll bender and sheet metal shears, metal benders. We have well trained and experienced team and fully equipped machining equipment to guarantee that we offer good quality metalworking machines.

Index

hydraulic shearing machine, sheet metal shear, hydraulic metal shear

Maanshan Jiashida Machine Tool Company

Add.: Bowang Industrial Park, Bowang District, Maanshan City, Anhui Province

Contact Person: Bert Chi

Fax: +86-555-6766722