- Home

- Products

- Shears

- QC12 Series Sheet Metal Hydraulic Swing Beam Shear

- QC12Y Sheet Metal Hydraulic Swing Beam Shear with E21S Controller

QC12Y Sheet Metal Hydraulic Swing Beam Shear with E21S Controller

Application of the QC12Y Sheet Metal Hydraulic Swing Beam Shear with E21S Controller

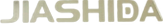

The QC12Y sheet metal hydraulic swing beam shear with E21S controller works by swinging its top blade to cut material. The shear angle of our equipment is small and the device features high shearing quality with excellent consistency. The machine adopts a swinging structure while it is made up of a machine rack, knife rest, blade gap adjustment system, material pressing system, front gauge, back gauge, hydraulic system, and electrical system.

The QC12Y sheet metal hydraulic swing beam shear with E21S controller is primarily used to shear stainless steel, iron, copper, and aluminum workpieces. Shearing machines are widely used in the aviation industry, light industry, metallurgical industry, chemical industry, architecture industry, shipbuilding industry, auto industry, power industry, electric appliance industry and decoration industry.

Parameters of the QC12Y Sheet Metal Hydraulic Swing Beam Shear with E21S Controller| Type | Max Thickness (mm) | Cutting length (mm) | Throat Depth (mm) | Shearing Angle (°) |

Blade length (mm) | Shearing speed (Cuts/min) | Back Gauge Specification |

Front Holder Quantity |

Motor Power (kw) |

Oil Tank Capacity(L) |

Weight (kg) |

L*W*H (mm) |

|||

| <450N/ mm2 | <700N/ mm2 | Travel (mm) | Speed (mm/sec) |

Number (PCS) |

Length (mm) |

||||||||||

| 4 | 2.5 | 2500 | 100 | l°30' | 2600 | 10~12 | 600 | 180 | 3 | 800 | 5.5 | 220 | 3800 | 3040*1610*1620 | |

| 4 | 2.5 | 3200 | 100 | l°30' | 3300 | 10~12 | 600 | 180 | 3 | 800 | 5.5 | 290 | 5000 | 3840*1610*1620 | |

| 4 | 2.5 | 4000 | 100 | 1°30' | 4100 | 8~10 | 600 | 180 | 4 | 800 | 5.5 | 290 | 6500 | 4600*1700*1700 | |

| 4 | 2.5 | 6000 | 100 | l°30' | 6100 | 5~7 | 600 | 180 | 6 | 800 | 11 | 380 | 11000 | 6460*2100*3200 | |

- Estun E21S CNC control system

- Back gauge location control

- Frequency inverter controls the back gauge

- HIWIN ball screws & polished rod with 0,05mm accuracy.

- Suspension arm and forearm supporting

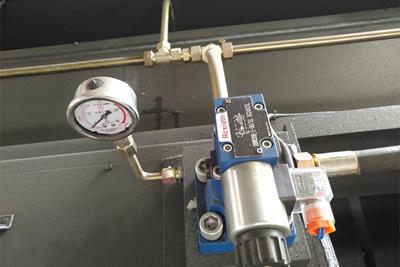

- Germany Bosch-Rexroth hydraulic valve

- Germany EMB oil tubing connector

- Germany Siemens main motor

- Electrics/France Schneider Electrics

- Hydraulic & electrical overload protection

- Light aligning

- The special blade material to cut the stainless steel

Estun E21S CNC Control System:

Intelligent location; Two channel programming digital output; Workpieces counting;

The QC12Y sheet metal hydraulic swing beam shear with E21S controller uses 40 procedures to storage data, and each procedure contains 25 processes;

Unilateral location and retract function;

One key backup and recovery function: CE certification

The workbench of the QC12Y sheet metal hydraulic swing beam shear with E21S controller is featured with rolling steel ball structure, as it decreases the friction of feeding material, protecting the workpiece surface, and also increases the security of the operator.

Siemens electrical components increasing the working lifetime of the QC12Y sheet metal hydraulic swing beam shear with E21S controller adapts and effectively decreasing the working noise of the machine;

America Sunny hydraulic oil pump; Long usage; steady operation

Rapidly manual blade edge gap adjustment; Operating and adjusting easily;

The QC12Y sheet metal hydraulic swing beam shear with E21S controller is assembled with Schneider electric components for stable operation.

When the electric cabinet door is open, the machine automatically shuts off as a safety feature.

The hydraulic control system of the QC12Y sheet metal hydraulic swing beam shear with E21S controller adopts a hydraulic valve supplied by Rexroth or First to control the up and down movement of the shear's cutting board.

Jiashida is a sheet metal fabrication equipment manufacturer and supplier, offering all kinds of sheet metal metalwork machinery like hydraulic shear, press brake, punch press, plate roll bender and sheet metal shears, metal benders. We have well trained and experienced team and fully equipped machining equipment to guarantee that we offer good quality metalworking machines.

Index

sheet metal shear, metal shearing equipment, hydraulic steel shear

Maanshan Jiashida Machine Tool Company

Add.: Bowang Industrial Park, Bowang District, Maanshan City, Anhui Province

Contact Person: Bert Chi

Fax: +86-555-6766722