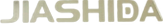

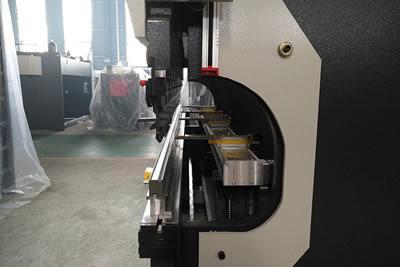

ESA S630 CNC Press Brake with Bidirectional Servo Pump

Description

The CNC press brake adopts BiD-SVP bidirectional pump electro-hydraulic servo system. BiD-SVP means bidirectional servo pump. The BiD-SVP bidirectional pump electro-hydraulic servo system has advantages of high energy saving, minimization of idle work, improvement of production efficiency etc., which can directly reduce much electricity expenditure for users, as well as minimize the consumption of hydraulic oil. In addition, it can greatly reduce CO2 emission and environmental pollution.

| Model | Bending Pressure (Kn) | Bending Length (mm) | Column Distance (mm) | Throat Depth (mm | Slider Stroke (mm) | Max. Opening Height (mm) | Yl,Y2-axis Down Speed (mm / sec) | Yl,Y2-axis Back Stroke Speed (mm / sec) | Y1,Y2- axis Precision (mm) | X-axis Max Distance (mm) | Workpiece Linear Degree (mm/m) | X&R Axes Accuracy (mm) | Sliding Front Supporting Stopper Arms (PCS) | Back Stopper (PCS) | Main Motor (Kw) | L*W*H(mm) | Weight (T) |

| 63T/1300 | 630 | 1300 | 950 | 350 | 100 | 340 | 150 | 150 | 0.01 | 500 | >0.3 | 0.05 | 2 | 2 | 5.5 | 3100*1450*2050 | 4 |

| 63T/2500 | 630 | 2500 | 1900 | 350 | 170 | 380 | 150 | 150 | 0.01 | 500 | >0.3 | 0.05 | 2 | 2 | 5.5 | 3100*1450*2050 | 5.8 |

Features

1. Energy saving: Compared with traditional transmissions, it saves 70% of power consumption.

2. High efficiency: The working efficiency can be improved by 30% (reduce the cycle time).

3. Accurate: The positioning accuracy is higher that can be up to 5um.

4. Quiet: Reduction of noise makes the machine tool quieter during work.

5. Less consumption: The hydraulic oil consumption is little, only 20% of traditional ones.

6. Easy: The machine tool is easier for manufacturing, maintenance and commission.

Advantages

1. Minimize overflow loss.

2. Stepless speed regulation. Adjustment range: 0 to maximum.

3. Set up proportional valve control to reduce throttling loss.

4. Accurate needed oil distribution optimized by the speed of dynamic servo motor.

5. Set up with idle power: the servo motor can be closed when no flow or pressure is required.

6. The unique design of normally open type of charging valve enables hydraulic compensation control.

7. Compact design, easier installation.

8. The difficulty of oil cylinder processing is lowered and the cost reduced.

9. For machine tool manufacturers, the change is small and easier for manufacturing.

Features of ESA-S630 CNC system:

1. Applicable for electro-hydraulic press brake, tandem press brake.

2. 10-inch touch screen

3. 2D graphics programming function

4. Fill-in programming mode, automatic calculation of press force and deflection compensation

5. Direct control of multiple servo valves without need for any external amplifier

6. All programs, molds and parameters can be saved to U disk through USB interface

7. Standard configuration: 4+1 axis control

Italian GIVI optical linear scale

1. Incremental optical linear scale with measuring step up to 5um or 1um

2. Built-in frictionless roller guide and ball bearing steel rod

3. Connecting rod for connection allows larger installation tolerances

4. Reference points optional per 50mm

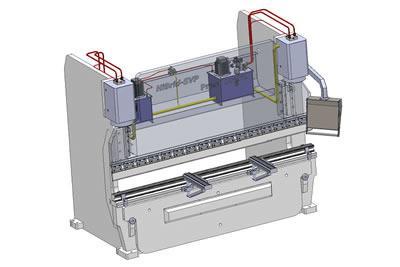

German ECKERLE bidirectional gear pump

1. Long service life, reliable performance

2. High volumetric and overall efficiency

3. Low noise, small pressure fluctuation

4. Excellent oil absorption, wide range of viscosity

5. Compact structure, easy maintenance

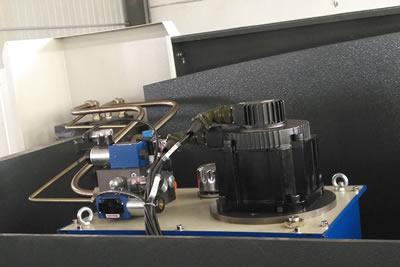

Electro-mechanical compensation

The deflection compensation mechanism of this machine adopts the mechanical deflection workbench compensation structure, with automatic calculation and control by numerical control system.

1. During working, the lower compensation workbench generates an upward force equivalent to the force of the main oil cylinder to the workbench, and thus an upward convex curve is produced to compensate the deformation of the workbench and the slider in the process.

2. Composed of a certain number of three-dimensional curved surfaces with different slopes that makes up for the shortcomings of the traditional hydraulic compensation blind zone, the compensation curve is closer to the real deformation curve of the slider, thus greatly improving the machining accuracy of the press brake.

Standard configuration includes a set of standard molds, portable and fast for mold replacement.

Adopting overall quenching process gives high hardness and good wear resistance.

1. Back gauge X axis R axis

2. High performance servo motor drive

3. With heavy load linear guide, large pitch ball screw drive, it is featured by high precision, high speed, good stability

4. Back gauge fingers 2 electric 2 manual

European style mold clamping interface

Equipped with fine tuning wedge block to adjust the fixtures' effective use height so as to ensure the flatness requirement between the fixtures.

With KACON foot switch, manual handle back gauge fingers adjustment, emergency stop switch button, to ensure operation safety.

The electrical system is mainly based on electrical components of French SCHNEIDER and equipped with high quality dust-proof electrical cabinets, which ensures its high quality.

Jiashida is a sheet metal fabrication equipment manufacturer and supplier, offering all kinds of sheet metal metalwork machinery like hydraulic shear, press brake, punch press, plate roll bender and sheet metal shears, metal benders. We have well trained and experienced team and fully equipped machining equipment to guarantee that we offer good quality metalworking machines.

Index

sheet metal press brake, electric press brake, metal bending machine